Laser Cut Hole in Silicon

-

by ivan

- 46

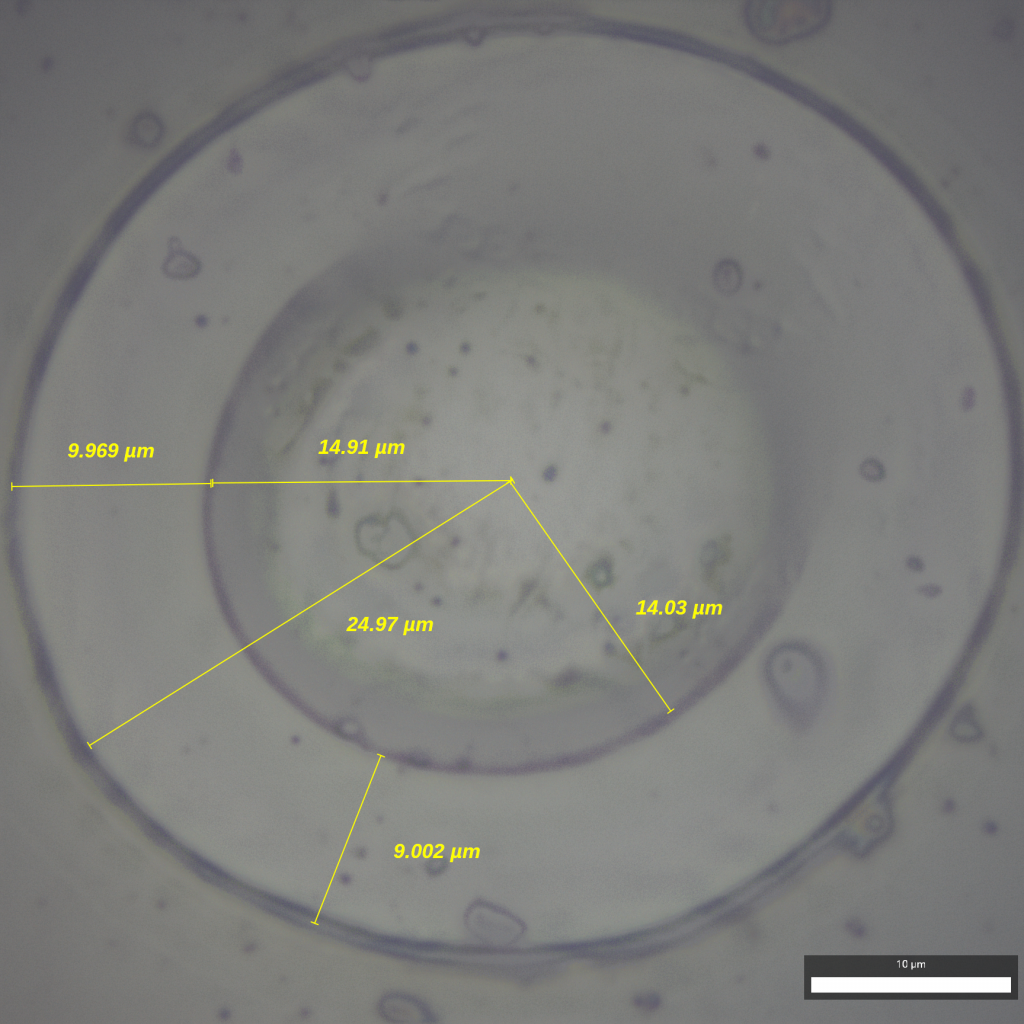

Sorin cut some holes in a silicon wafer using a laser beam. The microscope can easily measure the X and Y distances and size of the hole. By focussing on different parts of the hole, it is also possible to take measurements in the Z direction.

Debris from making the hole is scattered around the outside of the hole. The hole resembles a flattened hemisphere and the missing volume can be calculated using the formula for the volume of a sphere. The debris resembles a flattened half torus and its volume too can be calculated (estimated) from the formula for the volume of a torus. The two figures were found to match, to an acceptable estimation error; that is, nothing seems to have evaporated, disintegrated, been flung away etc.

The image below is created from the focus stacking software; it shows feature from both the debris and the hole, which would not normally be in focus at the same time.

Assuming the wafer surface is at depth 0, the debris mounted to height 1.1 microns and the hole sunk to a depth of 1.9 microns, giving a height difference of 3.0 microns.

Sorin cut some holes in a silicon wafer using a laser beam. The microscope can easily measure the X and Y distances and size of the hole. By focussing on different parts of the hole, it is also possible to take measurements in the Z direction. Debris from making the…

Sorin cut some holes in a silicon wafer using a laser beam. The microscope can easily measure the X and Y distances and size of the hole. By focussing on different parts of the hole, it is also possible to take measurements in the Z direction. Debris from making the…